Heat and Water Recovery from Flue Gas

Designed and implemented flue gas heat and water recovery system using condensing heat exchangers, achieving 2.5% efficiency gain and recovering 500+ cubic meters of water daily.

Key Results

Before & After Comparison

| Metric | Before | After |

|---|---|---|

| Stack Temperature | 150C | 95C |

| Water Recovery | 0 m3/day | 500+ m3/day |

The Challenge

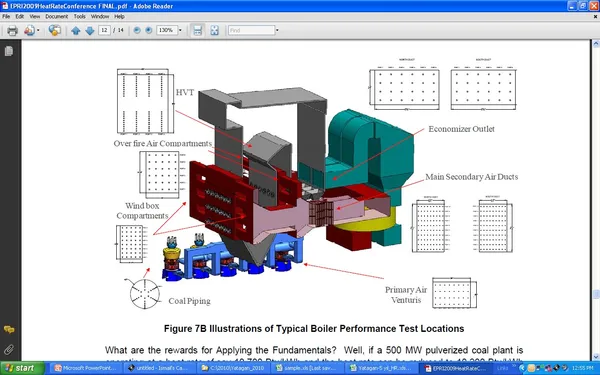

Flue gas leaving the stack contained significant recoverable heat and water vapor. This represented lost energy and water resources, while also contributing to visible plumes and potential environmental concerns in water-scarce regions.

Our Solution

TABi designed and implemented a flue gas heat and water recovery system using condensing heat exchangers. The system recovers both thermal energy for feedwater preheating and condensed water for reuse in plant processes.

Results Achieved

The system achieved a 2.5% efficiency gain through heat recovery, while recovering over 500 cubic meters of water daily for plant use. Stack temperature was reduced from 150C to 95C, eliminating visible plume.

Project Gallery