Our Projects

Real-world case studies demonstrating measurable efficiency gains, emissions reductions, and cost savings.

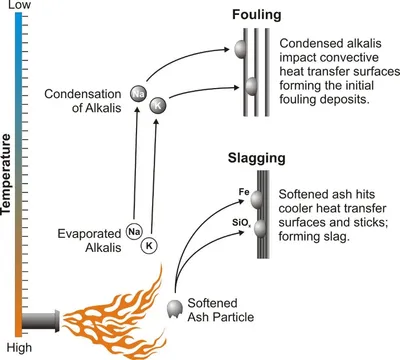

Slagging & Fouling Control Project - Indonesia

Comprehensive slagging and fouling control strategy for an Indonesian power plant, achieving significant reductions in cleaning frequency and improving plant availability through advanced diagnostics and targeted interventions.

Kayseri Seker Boiler Rehabilitation

CFD-driven combustion optimization achieving >99% CO reduction from 3000 ppm to <20 ppm, avoiding $21M natural gas conversion cost.

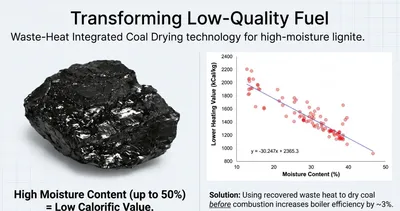

Waste Heat Integrated Coal Drying

Implemented low-temperature coal drying technology using waste heat to reduce lignite moisture content, achieving significant efficiency gains and emissions reductions.

Upgrade Assisted Combustion Optimization

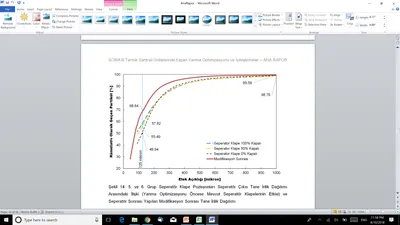

Comprehensive combustion optimization project combining classifier upgrades and air distribution improvements to significantly reduce unburned carbon and improve boiler efficiency.

Coal Flow Balancing and Combustion Tuning

Comprehensive coal flow balancing project that achieved 78% reduction in unburned carbon, transforming fly ash quality from unusable to marketable grade.

Advanced CFD Modeling for Combustion Optimization

Applied advanced Computational Fluid Dynamics modeling to achieve 99% reduction in CO emissions, from 3000 ppmv to 27 ppmv through iterative design optimization.

Slagging and Fouling Control

Comprehensive slagging and fouling control strategy that reduced cleaning frequency by 75% and improved plant availability through fuel management and temperature optimization.

Pulverizer and Classifier Upgrade

Upgraded classifier systems and implemented advanced coal flow balancing via TABi proprietary FCE mechanism, achieving 25% improvement in coal fineness and 60% reduction in flow imbalance.

Heat and Water Recovery from Flue Gas

Designed and implemented flue gas heat and water recovery system using condensing heat exchangers, achieving 2.5% efficiency gain and recovering 500+ cubic meters of water daily.

Field Services and Baseline Testing

Comprehensive on-site performance testing and baseline measurements that identified 3-5% efficiency improvement opportunities through data-driven optimization recommendations.

Ready to Optimize Your Energy?

Let our team of experts help you achieve measurable improvements in efficiency and sustainability.