Waste Heat Integrated Coal Drying

Implemented low-temperature coal drying technology using waste heat to reduce lignite moisture content, achieving significant efficiency gains and emissions reductions.

Key Results

Before & After Comparison

| Metric | Before | After |

|---|---|---|

| Coal Moisture Content | 45% | 32% |

| Plant Efficiency | 34.2% | 38.4% |

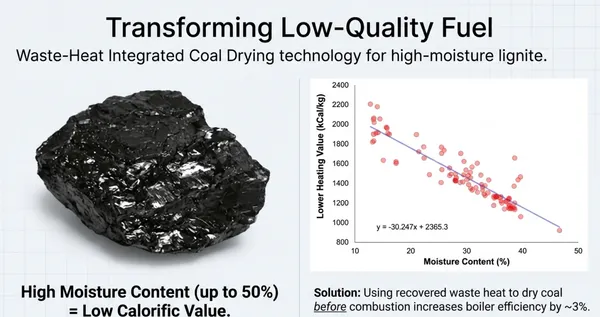

The Challenge

The power plant was operating with high-moisture lignite coal (45% moisture content), resulting in reduced combustion efficiency, higher fuel consumption, and increased emissions. Standard drying methods require significant energy input, reducing their economic viability.

Our Solution

TABi designed and implemented a proprietary low-temperature coal drying system that utilizes waste heat from flue gas. The system reduces coal moisture content before combustion without requiring additional energy input, integrating seamlessly with existing plant infrastructure.

Results Achieved

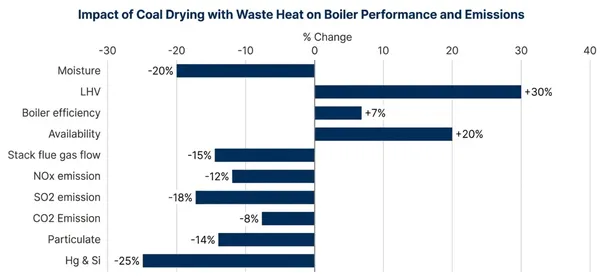

The project delivered measurable improvements across all key performance indicators. Plant efficiency increased by 4.2 percentage points, CO2 emissions dropped by 18%, and the system achieved full payback in less than two years through fuel savings alone.

Project Gallery