Advanced CFD Modeling for Combustion Optimization

Applied advanced Computational Fluid Dynamics modeling to achieve 99% reduction in CO emissions, from 3000 ppmv to 27 ppmv through iterative design optimization.

Key Results

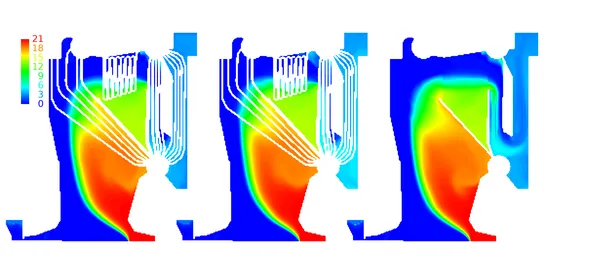

Before & After Comparison

| Metric | Before | After |

|---|---|---|

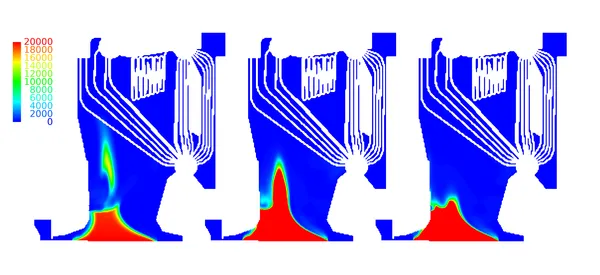

| CO Emissions | 3000 ppmv | 27 ppmv |

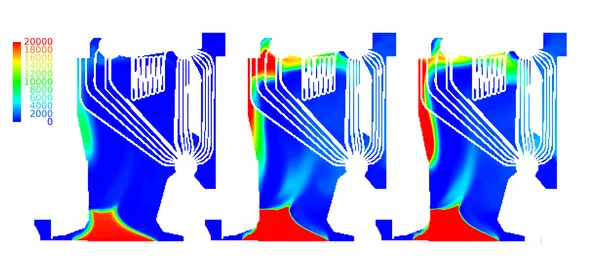

| CO (First Design) | 681 ppmv | 27 ppmv |

The Challenge

The industrial boiler had extremely high CO emissions (~3000 ppmv) indicating severe incomplete combustion. Poor air distribution and burner design resulted in wasted fuel and environmental compliance issues.

Our Solution

TABi employed advanced CFD modeling to simulate combustion patterns, air distribution, and heat transfer. Through iterative design optimization, multiple configurations were evaluated to find the optimal solution.

Results Achieved

The final optimized design achieved CO emissions of just 27 ppmv - a 99% reduction from baseline. The intermediate design effort brought CO to 681 ppmv, demonstrating the power of systematic CFD-guided optimization.

Project Gallery