Pulverizer and Classifier Upgrade

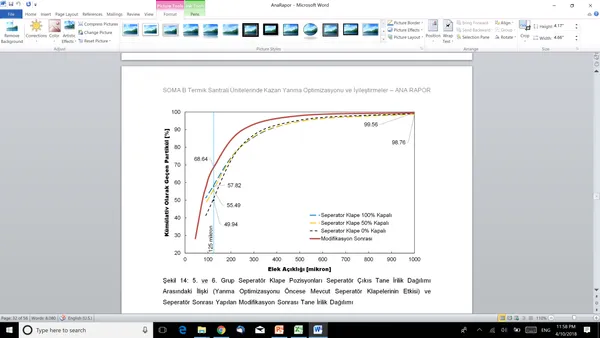

Upgraded classifier systems and implemented advanced coal flow balancing via TABi proprietary FCE mechanism, achieving 25% improvement in coal fineness and 60% reduction in flow imbalance.

Key Results

Before & After Comparison

| Metric | Before | After |

|---|---|---|

| Coal Fineness (75 micron) | 65% | 82% |

| Pipe Flow Imbalance | 15% | 6% |

The Challenge

Poor coal fineness from aging pulverizers and classifiers led to incomplete combustion, high unburned carbon, and reduced boiler efficiency. The existing equipment could not achieve the required coal fineness for optimal combustion, with significant flow imbalances among coal pipes.

Our Solution

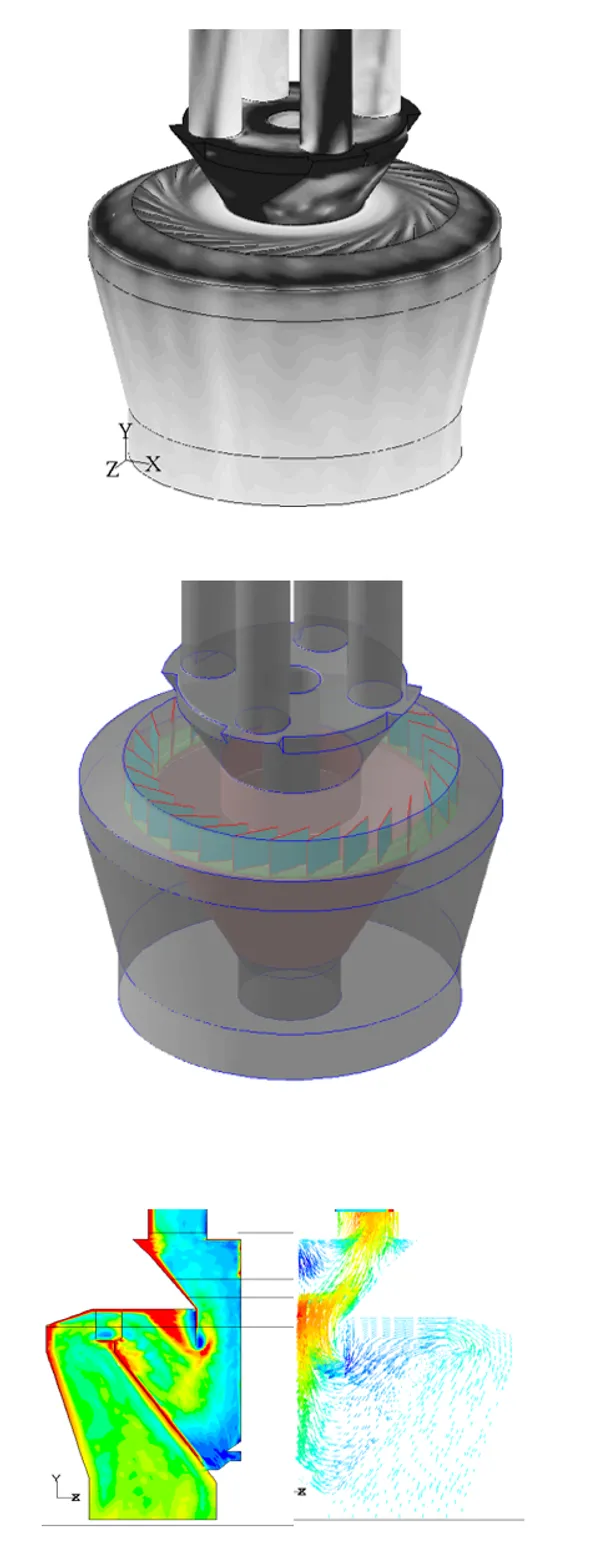

TABi upgraded the classifier system and optimized pulverizer operation using their proprietary FCE (Flow Control Element) mechanism for coal flow balancing in four-outlet vertical pulverizers. Multiple classifier adjustments were tested to find optimal settings.

Results Achieved

Coal fineness improved by 25% at the 75 micron sieve, with flow imbalances among 8 coal pipes reduced from 15% to 6%. The improvements led to better combustion, reduced UBC, and improved boiler efficiency.

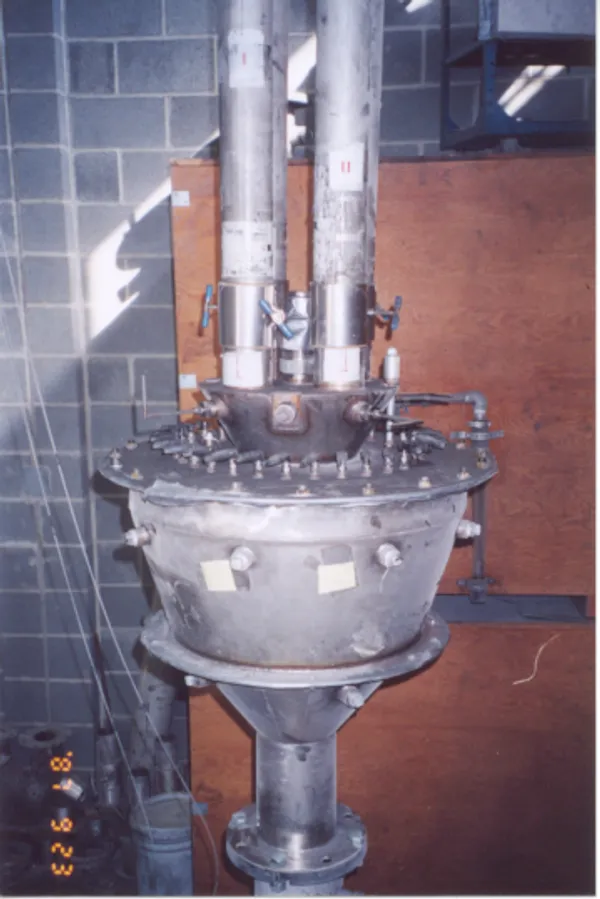

Project Gallery