Slagging and Fouling Control

Comprehensive slagging and fouling control strategy that reduced cleaning frequency by 75% and improved plant availability through fuel management and temperature optimization.

Key Results

Before & After Comparison

| Metric | Before | After |

|---|---|---|

| Cleaning Frequency | Monthly | Quarterly |

| Plant Availability | 88% | 96% |

The Challenge

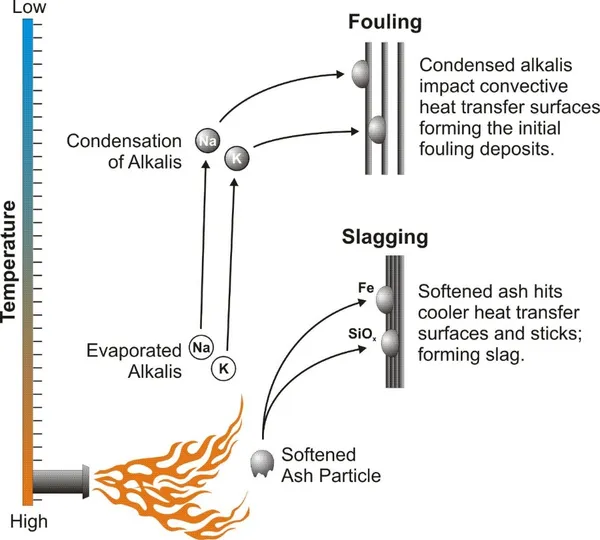

Coal-fired boilers frequently experienced severe slagging and fouling issues caused by ash deposition on heat transfer surfaces. These deposits reduced heat transfer efficiency, increased fuel consumption, and required monthly cleaning outages, significantly reducing plant availability.

Our Solution

TABi implemented a comprehensive slagging and fouling control strategy including fuel blending optimization, additive treatment programs, and furnace temperature management. CFD analysis was used to identify high-temperature zones prone to slagging and optimize air distribution.

Results Achieved

Cleaning frequency was reduced from monthly to quarterly, improving plant availability by 8%. Maintenance costs decreased significantly through prevention rather than remediation, and heat transfer efficiency was restored to design levels.

Project Gallery